To be Recognized Globally as a Lead in Mechanical Engineering through Excellence in Education and Innovative Research in Emerging areas.

To Provide Quality Education and Research with the State of the Art facilities to the Student: This is accomplished by:

1. Enhancing the Knowledge and Expertise through Professional Programmes and Research Works.

2. Endowing the Students with Academic Leadership, Communication Skills and Professional Awareness towards social Commitment

Established in the year 1984, the Department of Mechanical Engineering at Kalasalingam Academy of Research and Education is one of the oldest and the most prominent departments, dedicated to building a strong fundamental foundation and a thorough engineering orientation. It ensures to provide its students with an effective learning experience with state-of-the-art laboratories, experienced faculty, and thought-provoking teaching pedagogy. The curriculum is highly demanding and thoughtfully designed to incorporate all the latest development in the field. The department is constantly striving to attain excellence in academics, teaching, innovation, industry-oriented research, and consulting work with service to society. The programme is accredited by NBA for six years under the Tier-I category of the Washington Accord. The programme is also accredited by ABET, an international accreditation body for engineering and technical education.

The department offers a B.Tech program in Mechanical Engineering. The Courses have been created by a specialized team of academics and all the B.Tech. The students of Mechanical Engineering are trained with SAP training. The curriculum of Mechanical engineering aims at creating the right mindset which ensures the creation of innovative, thoughtful, and socially aware engineers.

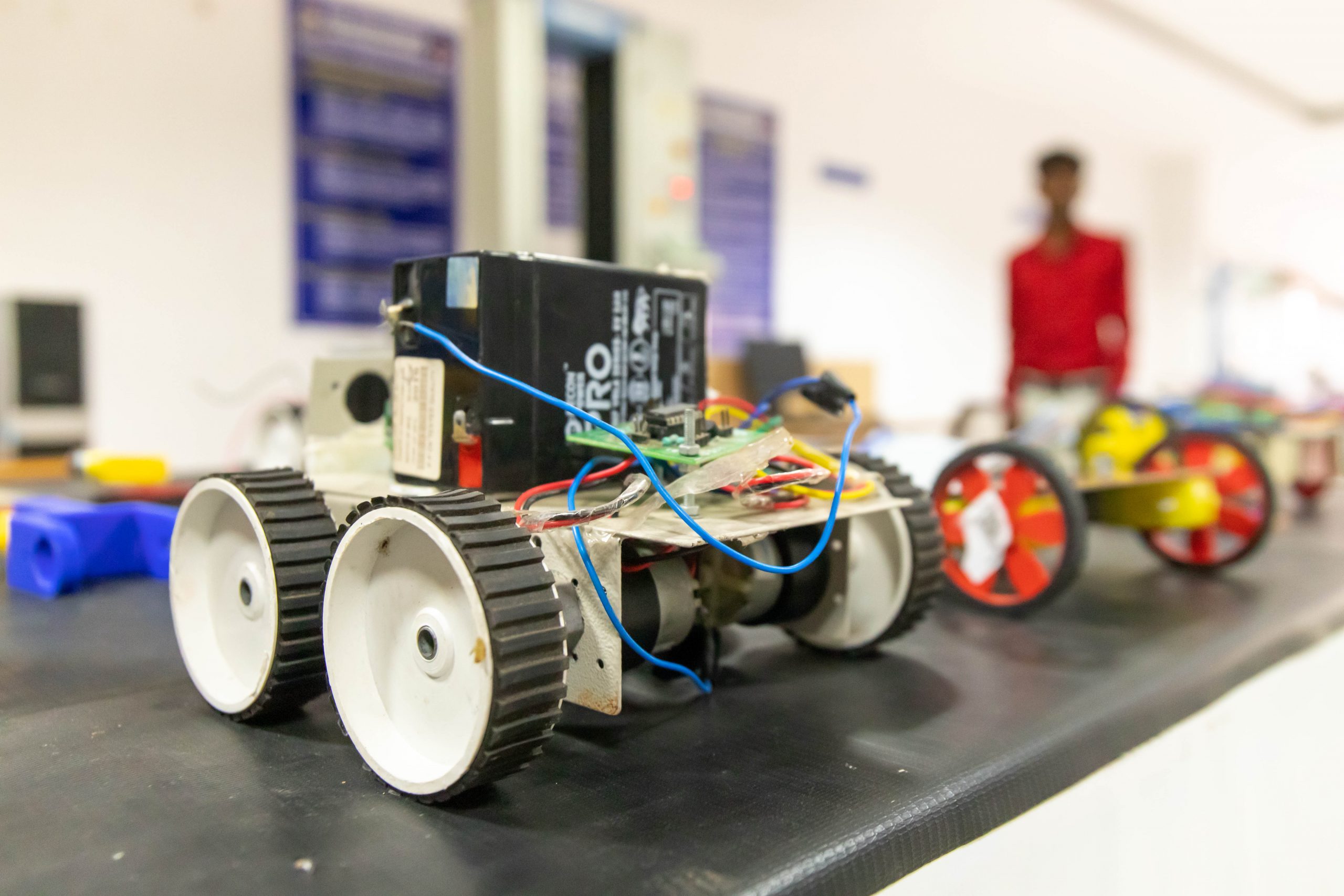

We believe in the practical nature of the domain and focus on learning by doing it practically. The department has active and vibrant students’ chapters of major professional bodies such as the Society of Automotive Engineers (SAE) and the National Safety Council (NSC) India. Through these societies, students get a hands-on experience of real-world challenges and a platform for organizing, participating, and developing engineering dreams. The Department also has a dynamic coordinating section completely dedicated to student’s Intellectual Property Rights (IPR) and Patents. Students are regularly participating in the “National and International events”

To ensure a smooth and effective practical learning experience, the Mechanical Engineering department at Kalasalingam Academy of Research and Education has established Robert Bosch Center of Excellence, Materials Processing Laboratory, Advanced Machining & Measurement Laboratory, and Machine Dynamics & Condition Monitoring Laboratory under Level 1 of the DST-FIST program (Fund for Improvement of Science & Technology Infrastructure in Universities & Higher Educational Institutions).

Thermodynamics Lab

Materials Lab

Labs

Labs

Labs

Labs

Labs

Program Educational Objectives (PEO)

Graduates of B.Tech.Mechanical Engineering will able to

PEO-1 : Graduates will apply fundamental technical knowledge and skills to find workable solutions to technological challenges and problems in diversified areas such as Production, Design, Thermal, Industrial and allied fields of Mechanical Engineering.

PEO-2: Contribute in providing solutions to sustainable economic development nationally and globally, developing as leaders in their fields of expertise.

PEO-3: Graduates will become entrepreneurs to confront business challenges or will continue their professional advancement through their knowledge horizon and inculcate lifelong learning.

Program Outcomes (PO)

PO1 – Engineering Knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

PO2 – Problem analysis: Identify, formulate, research literature, and analyse complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

PO3 – Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

PO4 – Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

PO5 – Modern Tool Usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modelling to complex engineering activities with an understanding of the limitations.

PO6 – The Engineer and Society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

PO7 – Environment and Sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of need for sustainable development.

PO8 – Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

PO9 – Individual and Team Work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

PO10 – Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

PO11 – Project Management and Finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

PO12 – Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Program Specific Outcomes (PSO)

PSO1– An ability to utilize the gained knowledge of mathematics and engineering sciences to real time problems involving thermal, design, manufacturing and materials domain.

PSO2– An ability to specify, fabricate, test, operate, validate and complete documentation of any basic mechanical systems or processes.

PSO3– An ability to apply the acquired software’s skills to design and analysis of advanced mechanical systems or processes.

ABET Student Outcomes (ASO)

ASO1 –An ability to identify, formulate, and solve complex engineering problems by applying principles of engineering, science, and mathematics

ASO2 – An ability to apply engineering design to produce solutions that meet specified needs with consideration of public health, safety, and welfare, as well as global, cultural, social, environmental, and economic factors

ASO3 – An ability to communicate effectively with a range of audiences.

ASO4 – An ability to recognize ethical and professional responsibilities in engineering situations and make informed judgments, which must consider the impact of engineering solutions in global, economic, environmental, and societal contexts.

ASO5 – An ability to function effectively on a team whose members together provide leadership, create a collaborative and inclusive environment, establish goals, plan tasks, and meet objectives.

ASO6 – An ability to develop and conduct appropriate experimentation, analyze and interpret data, and use engineering judgment to draw conclusions.An ability to develop and conduct appropriate experimentation, analyze and interpret data, and use engineering judgment to draw conclusions.

ASO7 – An ability to acquire and apply new knowledge as needed, using appropriate learning strategies..

This moulded them to develop 10 innovative products in 5 years. They have also got 23 patents and 55 publications under their name. The students have done wonders in the field of extracurricular activities apart from academics. The students took part in many National and International Events” and bagged lots of medals. The students of B.tech- Mechanical Engineering are offered a One Credit Course from the Industry and International Professors. The department invites resource persons from industries and abroad to handle one credit course in order to raise awareness and bring industrial skills to our students (15hours).

Most of the students from the B.Tech Mechanical programme doing their final year Project/ internships at industries/ International universities for a semester.